A topic I discuss very often in classes is the difference between Heat Release Rate and Temperature. This is a fundamental concept all firefighters need to understand in order to make sound decisions on the fireground. We all seem to grasp the reference of temperature very quickly because of how much we rely on temperatures in daily life. However, a candle on fire and a room on fire are two completely different things even if they are burning at the same temperature. The video above offers a very good introduction to the basics of heat release rate and temperature. This video is produced by the Firefighter Safety Research Institute (FSRI) and they have many more videos and resources available for you to learn about fire research and science. You can click here to visit the FSRI website or you can click here to visit their YouTube Channel.

Tru ID Hose with Dennis Legear

If you haven't heard of Dennis Legear or about his research from hydrants to nozzles you have to read up and watch this video. Dennis has provided the fire service with some great ideas and research and his latest project has come to fruition. Tru ID hose was a major effort by many to produce a spec of fire hose built with purpose and built to solve several critical issues. In the video below Dennis explains some of the reasoning and details behind the design and why this is important to every firefighter that rides the nozzle. If you would like to read more about his work visit his website at: www.hydrant2nozzle.com

Benefits of the Reverse Lay

Very rarely do we discuss the tactical advantages of different types of hose layouts for water supply. However, once you break down the movements and positional assignments of each type of hose lay you begin to see some advantages for different scenarios. The Reverse Lay offers several key advantages for limited manpower and residential structure fires. First let's look at the three main ways to lay out supply line.

Forward

The forward lay is very common and is typically used by the second due engine to supply the first due engine with a supply line. The second due engine stops at a nearby hydrant, drops a firefighter off to make connections and then proceeds to lay hose out to the attack engine.

Reverse Lay

The reverse lay is a popular lay in many different parts of the United States. The Reverse Lay is typically used by the second due engine to supply the first due engine with a supply line. The second due engine stops at the scene or the attack engine, drops a supply line off to make connections and then proceeds to the hydrant.

Split Lay or Blind Alley

The Split Lay is great for confined areas like long narrow driveways, alleys, tight streets with limited access and dead ends. The split lay is typically initiated by the first due engine when they recognize an access problem. The first due engine drops their supply line in an intersection or location before the confined area and then proceeds to the fire. The second due engine lays a line to the first due's supply line. This creates two different hose lays that meet in the middle. The split lay helps to keep other companies from getting jammed into a tight spot while trying to position on a fire.

In the video below we discuss the 3 different types of hose layouts but also go into more detail about the advantages the Reverse Lay has to offer.

https://youtu.be/uunsCzuSv5M

Determining Flow Through Nozzle Reaction

Determining Flow Through Nozzle Reaction

Recently I completed my first year of the Executive Fire Officer Program at the National Fire Academy. If you are unfamiliar with the EFO program you must submit an Applied Research Project (ARP) for each year during the process. I wanted my ARP to identify a unique problem that really hasn't been discussed much in order to provide the fire service with some new information regarding the way we train firefighters to operate the nozzle during interior fire attack operations.

During my time as a firefighter and instructor I have noticed very few firefighters actually pay attention to the amount of water they are delivering at the nozzle. They just take it for granted that the water leaving the nozzle is what it is "supposed to be". During early stages of Driver Operator training we learn about friction loss and proper pump discharge pressure in order to achieve the proper nozzle pressure which in turn delivers the target flow we need. However, no one really discusses what happens at the nozzle and whether or not the firefighter can actually feel the difference in flow to know if something isn't operating correctly. We tend to look at nozzle reaction as a theoretical math problem instead of a tool we could use to identify problems that occur on the fire-ground.

The first step involved in this research process was to determine if there actually is a problem. A problem with curriculum, training, or even drills that have left the firefighter unprepared. My first ARP was to identify this problem so that in subsequent ARPs I could address solutions to this problem. However, I have tested some solutions and we are already seeing a trend which I believe can better prepare interior firefighters.

In the first ARP I tested an NFPA 1001-I-II class in their final week of training to see if they were able to identify critical reductions in flow. The results showed that 46% of the students were unable to detect a 25% reduction in flow using nozzle reaction. This test reduced a 125gpm @ 100psi nozzle by 25% simulating a 180 degree kink which could occur on the fire-ground. This 25% reduction drops the flow of the nozzle to around 94gpm which is below the recommended flow rate in NFPA 1710.

I believe my results show that we could do more to train firefighters working on the nozzle to identify potential problems. That being said we performed the same test to a group of students that just finished a week long advanced Engine Company Operations course and we found that 90% of our students detected a 10% reduction in flow. These firefighters received training in several nozzle operation techniques and performed a very high number of repetitions throughout their week of training. The feedback we received from the course was very positive and the firefighters that participated felt like they truly refined their skill sets.

I have provided a short video discussing these results and some recommendations I have for training your firefighters to identify critical reductions in flow. If you would like to read the full ARP you can CLICK HERE to read all of the details.

Scott Sight - FDIC 2016

Scott released it's newest innovation at FDIC 2016, the Scott Sight. We had a great opportunity to check out this brand new device and from what we have seen so far the future of thermal imaging is very bright. Immediately the very first question firefighters ask is "How much does it cost?" knowing that this technology must be out of reach. However, Scott shocked most firefighters when they announced the list price on the entire system (Mask and Imager) would be around $1,875. They were selling the Scott Sight system, as a show special, at FDIC for less than $1000. We were very fortunate to meet with a very well educated representative from Scott who explained many intricate details behind the product's success. I wanted to break down a few of the key discussion points to help all of you find the answers to the questions you may have. We have provided two videos for you to check out below followed by our breakdown of the key questions.

The Scott Sight

https://www.youtube.com/watch?v=r4Y-furscmY

Our live Periscope Broadcast from FDIC 2016

https://www.youtube.com/watch?v=JqqrQsaVQ8o

How much does it weigh?

The Scott Sight reportedly weighs just 4 ounces. When we think about the weight of accessories on the face piece we generally do not want any extra weight than necessary. This system is very light considering the value of having an in-mask thermal imaging system. You also have to realize the imager itself rides just in front of your ear. This places the imager in a really good center of gravity point and does not feel like it pulls the face piece down like some of the other accessories.

How good is the image?

The image is surprisingly good considering how small the display actually is. We were told the system actually delivers an image that represents a distance of about 12 feet away. So, you would think that firefighters wearing glasses may struggle seeing the image when they actually can see the image fairly clearly because the focal point is so far away. The display itself rides on a hinge system just above the nose cone and is adjustable up and down using a small tool. This lets you line the display up to each firefighter's personal preference.

What kind of batteries does it use?

Right now the system uses standard AAA batteries but I could see this turning into a rechargeable system in the future. We were told they were seeing close to 4 hour run times during FDIC.

How do you clean the Scott Sight?

The entire system can be dunked into a cleaning solution. However, you can actually remove the entire camera from the mask if you want to perform a better cleaning job. The lens is held in with a removable bezel which can be removed to clean the lens if you have trouble getting debris out of the small opening.

What information is on the display?

Right now you can see standard information like air and battery levels. This system could be used to send a lot more information in the future. Just think about information we can already gather like accountability info or breathing rates, etc. Basically any data we can obtain could be pushed to the face piece in the future. This opens the door to many interesting concepts.

All in all this is a really exciting system and I look forward to seeing what is in store for the future.

Nozzle Air Entrainment - The Cause and Effect

We have recently produced a video series discussing Nozzle Air Entrainment for firefighters. In this series we took a look at 3 pairs of tests for a total of 6 videos. In this video we take an in depth look at nozzle air entrainment and hope this overall instructional video sheds a little light on the topic. Remember, you can reference the other test videos by viewing them in the overall Nozzle Air Entrainment Playlist. We will provide that playlist at the bottom of this article, but you will also be able to find the playlist on our website by clicking here or on our YouTube channel.

Nozzle Air Entrainment - The Cause and Effect

https://www.youtube.com/watch?v=aASbS63Ki4o

If you missed the other videos you can find them in our playlist below:

https://www.youtube.com/playlist?list=PL4NKqZJ7joymMNcArOH8teKL_c2u6X3KJ

Nozzle Air Entrainment Round 3 - Video Series

This is the third round of videos in our Nozzle Air Entrainment Video Series. In this round of test videos we will look at interior ventilated attacks with both the fog nozzle and the smoothbore nozzle. If you haven't seen the first or second round of tests you can view them by clicking here: First Round, Second Round

TEST 5 - Fog Nozzle Ventilated Attack

https://www.youtube.com/watch?v=bI4wdp3dvf4

TEST 6 - Smoothbore Nozzle Ventilated Attack

https://www.youtube.com/watch?v=GXpHMxxjr4Q

Thank you for watching. Keep an eye out for the next video in this series which will recap all the test and review the nozzle types and attack methods. We will also include some thermal imaging footage during some test burns. If you would like to view the entire playlist on YouTube you can view it below:

The Entire Nozzle Air Entrainment Playlist:

https://www.youtube.com/playlist?list=PL4NKqZJ7joymMNcArOH8teKL_c2u6X3KJ

True Hose Spec Push 2016

For many of us we find ourselves slipping into conversations that have to do with firemanship, passion, commitment, tactics and change. If any of those describe you, it is time to make a push. Dennis LeGear from LeGear Engineering F.D. Consulting has been making waves with many ideas such as the 1 3/16" nozzle and the potential for making a true hose spec built for purpose.

The True Hose Spec Project is an effort to manufacture hose with true internal diameter which will greatly benefit all of us by reducing hose whip, kinking, elongation and many other problems associated with "swelled" diameter hose.

For many of us we find ourselves slipping into conversations that have to do with firemanship, passion, commitment, tactics and change. If any of those describe you, it is time to make a push. Dennis LeGear from LeGear Engineering F.D. Consulting has been making waves with many ideas such as the 1 3/16" nozzle and the potential for making a true hose spec built for purpose.

The True Hose Spec Project is an effort to manufacture hose with true internal diameter which will greatly benefit all of us by reducing hose whip, kinking, elongation and many other problems associated with "swelled" diameter hose.

So, how can you help? Dennis needs support for this project and wants to show the manufacturers that all of us desperately need a better hose spec. All you have to do is go to the link below and fill out the form. He will take this information straight to the manufacturers to continue the push for True Hose Spec.

CLICK HERE FOR THE DESCRIPTION ARTICLE LINK TO THE TRUE HOSE PUSH 2016

CLICK HERE TO SUPPORT AND FILL OUT THE FORM TO SUPPORT THE TRUE HOSE SPEC

Nozzle Air Entrainment Round 2 - Video Series

This is the second round of videos from our Nozzle Air Entrainment Video Series. In these two videos we will look at the interior attack of a vent limited situation. This will give you a good idea of how a nozzle can over pressurize a space regardless of fire or heat. This is simply air entrainment causing this over pressurization. We will use two videos, one for the smoothbore and one for the fog nozzle. This will pick up where we left off with Tests 1 & 2. If you haven't seen the first two tests click here to watch those videos.

TEST 3 - Fog Nozzle Interior Attack Vent Limited

https://www.youtube.com/watch?v=MKWrYKUIvpc

TEST 4 - Smoothbore Nozzle Interior Attack Vent Limited

https://www.youtube.com/watch?v=2q-CaiklzyI

Thank you for watching and keep an eye out for the next round of videos. We still have two more experiments to go and will release those next week.

If you would like to view all of the videos in the video series you can see them below in our playlist:

Entire Nozzle Air Entrainment Playlist

https://www.youtube.com/playlist?list=PL4NKqZJ7joymMNcArOH8teKL_c2u6X3KJ

Nozzle Air Entrainment - Video Series

Today we have released the beginning of a 7 part video series on Nozzle Air Entrainment. These videos will walk through some of the basic concepts of nozzle air entrainment and how you can deliver some hands-on practical drills demonstrating air entrainment with various nozzle types. We will release all of these videos over the next few weeks so keep an eye out as we move along. You will see below Test 1 and 2 which will begin our video series.

TEST 1

Test 1 is an exterior attack through a window using a fog nozzle. We will begin the attack with a straight stream directed at the ceiling and then move the pattern through 30 degrees and towards full fog. You will see a drastic increase in air entrainment as we change the pattern of the nozzle. This fog nozzle was flowing 125 GPM at 100 psi nozzle pressure.

https://www.youtube.com/watch?v=k1xpO9Es2nY

Test 2

Test 2 is the same test but we are using a 7/8" smoothbore nozzle. You will see a decrease in the air entrainment even with the increase in flow. This 7/8" tip was flowing 160 GPM at 50 psi nozzle pressure.

https://www.youtube.com/watch?v=EOmyrJEpIZw

You will see several more of these tests coming out over the next few weeks. The next tests include interior attacks both ventilated and non ventilated.

If you would like to view all of the videos in the video series you can see them below in our playlist:

Entire Nozzle Air Entrainment Playlist

https://www.youtube.com/playlist?list=PL4NKqZJ7joymMNcArOH8teKL_c2u6X3KJ

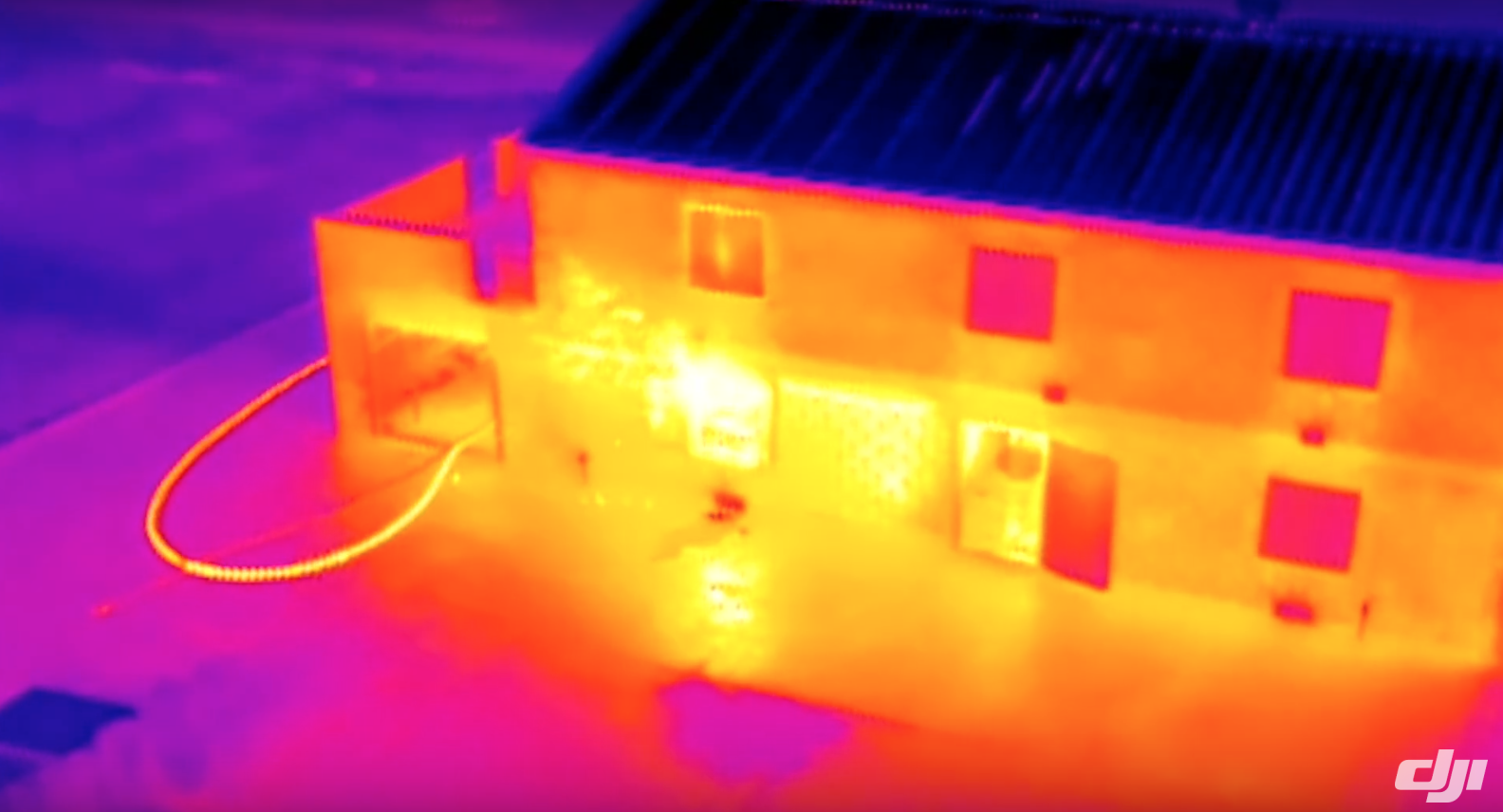

DJI and FLIR Imaging Video

As technology in the UAS (Unmanned Aircraft Systems) rapidly moves forward DJI has just released its partnership with FLIR to provide thermal imaging on board their current UAS platforms. This will be a topic for many of us performing fire and SAR operations.

As technology in the UAS (Unmanned Aircraft Systems) rapidly moves forward DJI has just released its partnership with FLIR to provide thermal imaging on board their current UAS platforms. This will be a topic for many of us performing fire and SAR operations.

Check out the video below to see the features and how this system could be used.

https://www.youtube.com/watch?v=Z625R9eljIc

UL - Air Entrainment Research

UL's Firefighter Safety Research Institute has conducted an extensive Air Entrainment Study to evaluate the influence of nozzles and their ability to influence the flow path during a fire. I personally have been conducting my own back yard testing for more than a year on this very topic. From the moment "You can't push fire" was quoted I began to evaluate the entrainment of air using various nozzles and application techniques. I am looking forward to seeing the results UL publishes so we can have a better understanding of this dynamic environment. I will release several training videos in the near future about this very topic but until then check out UL's video about the study. https://www.youtube.com/watch?v=N7pMy_bl2Vs

You can read below to see what UL has to say about this valuable research project:

As part of the 2013 DHS Grant to study the “Impact of Fire Attack utilizing Interior and Exterior Streams on Firefighter Safety and Occupant Survival” testing was conducted at the Delaware County Emergency Services Training Center in Sharon Hill, PA to measure the amount of air being entrained into the structure by Fire Attack operations. Each test was designed to evaluate differences in entrainment, if any, by looking at different nozzle types, stream types, application patterns, as well as different compartment and ventilation configurations. These tests were conducted over a four day period where more than 150 tests were performed resulting in tens of thousands of data points as well as hours of video and hundreds of still images.

These experiments were conducted in a two-story residential structure with concrete walls and drywall constructing the first floor, and normal wood framing with drywall constructing the second floor. The building size was 20ft. wide, 36ft. long with 8ft. high ceilings. The building had multiple ventilation openings varying in size which allowed tests to be done utilizing different variables to replicate the most realistic conditions firefighters would face in the field. Additionally, the interior geometry of the structure was varied dependent on the type of test being conducted.

Instrumentation was used to measure air flow into the structure caused by the type of hose stream and how it was applied. These devices included bi-directional probes and associated pressure transducers to measure air flow in addition to in-line pressure and flow gauges to ensure the hose streams were applied at the desired pressure and flow per the manufacturer.

The tests covered a range of hose line sizes including 1-3/4” and 2-1/2” as well as different nozzle types: combination/fog and smoothbore. Portable monitor and master stream devices were examined as well. The hose streams varied between smoothbore, straight stream, and narrow fog in addition to the nozzle patterns including fixed, “Z,” “O,” and the Inverted “U.” The first round of experiments was aimed at determining the amount of air entrained by the different nozzles at different hose line sizes and application patterns irrespective of building configuration. The next series of tests examined the impact of varying the ventilation openings both behind and ahead of the nozzle. The final series of experiments focused on a more realistic interior geometry layout involving flowing water while moving down a hallway towards a room. Once again, ventilation openings were varied ahead of the nozzle. During each of these series of experiments, hose streams were applied from both the interior and exterior of the structure to determine the differences in overall entrainment into the structure.

Boston MAYDAY Training Video

This is a great MAYDAY training video from Boston Fire Department. Very well put together and even if your MAYDAY procedures differ from Boston you will still get tremendous benefits watching this video with your crew: https://www.youtube.com/watch?t=461&v=oCvkRLtk-_w

Nozzle Series - Smoothbores

The Smoothbore Nozzle

We are continuing our video series on nozzles with the Smoothbore. This nozzle remains a powerhouse in the American Fire Service. With the increase in heat release rates due to changes in products and materials our ability to throw serious water on the fire is of the utmost importance. The smoothbore nozzle offers several advantages for firefighters. Some of strongest advantages come with the simplistic design of the nozzle. The smoothbore has the ability to perform under extreme conditions with good flow at a low nozzle reaction. The nozzle is very difficult to clog with debris and if a hose line becomes kinked it will maintain fairly good flow compared to a high pressure fog nozzle (100 psi). Even though the fog/combination nozzle has the ability to absorb more heat energy at the same flow, the smoothbore has the ability to penetrate without steaming off when attacking the fire. Once the stream enters the room on fire we can bounce the stream off of walls and ceilings to break up the stream and increase its heat absorption capabilities. The video below will provide you with an overview of the smoothbore nozzle and will cover a few topics in detail.

We are continuing our video series on nozzles with the Smoothbore. This nozzle remains a powerhouse in the American Fire Service. With the increase in heat release rates due to changes in products and materials our ability to throw serious water on the fire is of the utmost importance. The smoothbore nozzle offers several advantages for firefighters. Some of strongest advantages come with the simplistic design of the nozzle. The smoothbore has the ability to perform under extreme conditions with good flow at a low nozzle reaction. The nozzle is very difficult to clog with debris and if a hose line becomes kinked it will maintain fairly good flow compared to a high pressure fog nozzle (100 psi). Even though the fog/combination nozzle has the ability to absorb more heat energy at the same flow, the smoothbore has the ability to penetrate without steaming off when attacking the fire. Once the stream enters the room on fire we can bounce the stream off of walls and ceilings to break up the stream and increase its heat absorption capabilities. The video below will provide you with an overview of the smoothbore nozzle and will cover a few topics in detail.

https://www.youtube.com/watch?v=tgzHmYZ3BUo

Amazing Rescue Footage from Peoria

Many of you have seen videos from Peoria Fire Training before. In the past they have produced several very good training videos. I still continually hear and read all the negative comments regarding social media, helmet cameras and footage of fire scenes. I know there can be many negative things happen from using this footage but the benefits are incredible if used correctly. This is one of the few videos I have seen that actually allows us to see all of the working components involved in this rescue. If you are an instructor or company officer this video provides you with an incredible resource to use for training and preparing for these situations. https://www.youtube.com/watch?v=M8V4H59lQYg

New High-Rise Pack Innovation - QuickLay Fire Attack

https://www.youtube.com/watch?v=km9ETzhw7i0 QuickLay Fire Attack has introduced their brand new Attack Pack and Lay Pack for the American Fire Service. I had an awesome opportunity to meet and talk with Sebastian Jacobs, the Managing Director of QLFA, about his innovative high-rise pack system. Sebastian is from Australia and developed this high-rise pack after seeing the "Cleveland Load" hose lays that gained popularity in the United States. He designed a pack to not only carry the hose but to become part of a hose management system to increase efficiency on the fireground. The premise of the design is to establish two packs to deliver 200' of 1.75" hose in a variety of situations.

The Attack Pack is designed to carry 100' of 1.75" hose in a Cleveland Load so that you can deliver a manageable attack hose closest to your entry point. This pack can also be used for a wide variety of hose stretches we very commonly use such as the extended attack, wye'd lines, courtyard stretch, skid load, etc. The Attack Pack has no buckles or zippers and has a very streamlined designed to make carrying and advancing the hose much more efficient. With no buckles you can easily deploy the pack by pulling the "deployment strap" or with sufficient pressure the pack will self deploy when the hose line is charged.

The Attack Pack is designed to carry 100' of 1.75" hose in a Cleveland Load so that you can deliver a manageable attack hose closest to your entry point. This pack can also be used for a wide variety of hose stretches we very commonly use such as the extended attack, wye'd lines, courtyard stretch, skid load, etc. The Attack Pack has no buckles or zippers and has a very streamlined designed to make carrying and advancing the hose much more efficient. With no buckles you can easily deploy the pack by pulling the "deployment strap" or with sufficient pressure the pack will self deploy when the hose line is charged.

When the Attack Pack is used in situations like high-rise fires or standpipe operations you can use the Lay Pack to bring a water supply to the Attack Pack. The Lay Pack will also carry 100' of 1.75" hose but is loaded with an Accordion Load. This allows the Lay Pack to make the standpipe connection and then the hose will flake out of the pack while it is carried toward the Attack Pack.

For more information on QuickLay Fire Attack you can visit their website at www.quicklayfireattack.com.

BullEx Live Fire Demonstrations at FDIC 2014

I put together a few quick clips from the FDIC 2014 BullEx live fire demonstrations for you to see. They showed off their Gas-Fired training props and their Digital Fire training props. During the live fire demonstration you can see them attacking a pressurized vessel fire simulating something like a propane tank with a pop-off valve. You will also see them entering a structural fire prop with a Gas-Fired prop on the first floor and a Digital Fire prop on the second floor. The BullEx Digital Fire training system uses a screen to produce the "fire" image and a smoke machine to generate the smoke inside the structure. You can use a nozzle to attack the fire and the screen senses the flow and will dim as you extinguish it. It produces a very realistic look inside when combined with the smoke generator.

I put together a few quick clips from the FDIC 2014 BullEx live fire demonstrations for you to see. They showed off their Gas-Fired training props and their Digital Fire training props. During the live fire demonstration you can see them attacking a pressurized vessel fire simulating something like a propane tank with a pop-off valve. You will also see them entering a structural fire prop with a Gas-Fired prop on the first floor and a Digital Fire prop on the second floor. The BullEx Digital Fire training system uses a screen to produce the "fire" image and a smoke machine to generate the smoke inside the structure. You can use a nozzle to attack the fire and the screen senses the flow and will dim as you extinguish it. It produces a very realistic look inside when combined with the smoke generator.

BullEx also had their dumpster and grill live fire props for you to view. These are propane fired props controlled remotely. Lastly, take a look at the inside view of the new digital fire training system.

Fire Attack for the Modern Era

If you have your ear to the ground on the latest research in fire tactics then you should be familiar with some of the findings that have come to light. The LA County Fire Department has put together a really good video on one of the most common bread and butter fire attack methods that nearly all of us have in our play books. Take a look at the video below and if the tactical recommendations surprise you then read into this article a little deeper. There are many things you should know about the modern fire behavior concerns we have.

For more information on the latest fire research check out “Scientific Research for the Development of More Effective Tactics” – an online course that serves as a culmination of the full-scale field experiments performed on Governors Island by the Fire Department of New York, NIST and UL. UL FSRI Director Steve Kerber shared, “This training program presents the most up to date fire dynamics research in a way firefighters at all levels can comprehend. It builds off of all of the UL and NIST firefighter research to date and provides students with the science they need to examine their tactical approaches. Tactical considerations are presented with video and data in a way that is easy to understand. For the firefighters out there that want all the details, buttons allow access to all of the data graphs, experimental video and relevant FDNY procedures.”

CLICK ON THE PATCH BELOW TO GO TO THE NEW ONLINE COURSE!

Understanding the most up to date research and attack methods will help you make the right decisions on the fireground. While no course can prepare you for the real world, this information will definitely fit in your toolbox. This is a great course to share with your crews. Feel free to comment in the section below or if you have any questions feel free to contact us.

Firefighter Bailout! Are You Ready?

As firefighters, we often feel invincible and believe that we will always be able to perform whatever duty we are called to perform without negative consequences. At the same time, we are continually reminded every couple of days that we are not invincible with the announcement of another line of duty death. Take a look at the video. Would you be able to escape if ladders had not been in place? How about on an upper floor out of reach of a portable or aerial ladder?

Many people discount the need to be ready to bale because a lack of hi-rise buildings in their district. According to NFPA & OSHA statistics, 90% of all falls from a distance of over 10' are fatal when free falling a distance of 10' or greater. If you operate in a two story or taller building, it would be smart to be prepared.

Although every major turnout manufacturer that I know of is offering a firefighter bailout kit or escape harness, many fire departments are not purchasing them due to the added cost and trying to operate on already thin budgets. As firefighters, this leaves us on our own to do what is necessary to be prepared in terms of training and equipment should we have to make an emergency escape. What follows is a ridiculously easy and relatively inexpensive option to be prepared.

Many turnout manufacturers are now offering turnouts with nylon belts and plastic quick connect buckles instead of suspenders. These pants already have loops, Velcro tabs, or both to keep the belt attached to the pants. If you are currently wearing this style pant, remove that belt. All it is good for is holding your pants up. Replace it with whatever truck style belt you already have or can afford.

These are the same pants, but the supplied belt is removed and replaced with a “Gut Belt” that I had hanging in my locker. In addition to holding my pants up, this belt:

- Is manufactured to NFPA 1983 requirements for ladder/escape belts.

- Rated at 8000 lbs.

- Can increase visibility if equipped with reflective and/or fluorescent trim.

- Has hardware that exceeds NFPA load specifications.

- Has multiple points of attachment.

- Can be utilized with existing factory loops and tabs.

- In conjunction with other equipment for personal escape and firefighter rescue, would be far more effective than a nylon belt and plastic buckle. Also useful with, ladder work, carrying other tools or accessories, tags lines, etc.

What if you’re using turnout pants equipped with suspender tabs and no loops or tabs to hold a belt? No problem with these inexpensive velcro loops that hang on your suspender tabs. These are not holding any weight. They just provide a means to keep an escape/ladder style belt on your pants so it can easily be utilized. These are manufactured by Extreme Rescue. I picked them up at FDIC. You can visit their website at xtremerescue.com.

What if you’re using turnout pants equipped with suspender tabs and no loops or tabs to hold a belt? No problem with these inexpensive velcro loops that hang on your suspender tabs. These are not holding any weight. They just provide a means to keep an escape/ladder style belt on your pants so it can easily be utilized. These are manufactured by Extreme Rescue. I picked them up at FDIC. You can visit their website at xtremerescue.com.

For me, this is a good option to provide a balance between purchasing and dealing with the bind of a complete escape or rappelling type system with leg loops and being completely unprepared.

Lastly, keep in mind this is part of a system. A belt alone will not do you any good without at least a carabiner, a section of rope (how much is up to you), and practice, practice, practice.

If you have ideas, questions, concerns, or comments; please post them below or on our Facebook page.

*I am not associated with, nor profit from anything affiliated with Xtreme Rescue.

Situational Awareness Video

This is a very good video put together by Peoria Fire Training. The video details a strip mall fire on 99th Avenue just north of Peoria in Arizona. Take a look at the video, share it with others, and take a look at some of the information below.

Situational Awareness and Decision Making

As firefighters we often face a multitude of decisions that need to be made at a moments notice. This situations are very hard to prepare for on the spot, they must be churning in your mind before they happen. Fundamentally what we do at a structure fire hardly ever changes. However, the situation we are faced with is never the same. We must rely on those fundamental play calls that every department should have down to a science. Then when we encounter extraordinary situations we have the ability to audible to a solution.

So, if we have the plays mastered and we have rolled scenarios through our minds prior to the incident then our primary focus should be to recognize the blind side that can come at any moment. All other functions on the fireground should be fluid and understood so that we remain open to audibles and call them when we need to.

Hats off to the Peoria Fire Department for sharing this information. With training videos like these thousands of firefighters can learn from their experiences and recognize those red flags that are present on many of our day to day incidents.